Interview of Stephane Lhuisset, Chief Technical Officer at Asystom. Stephane is one of the founders of the company.

What is AsystomAdvisor Platform?

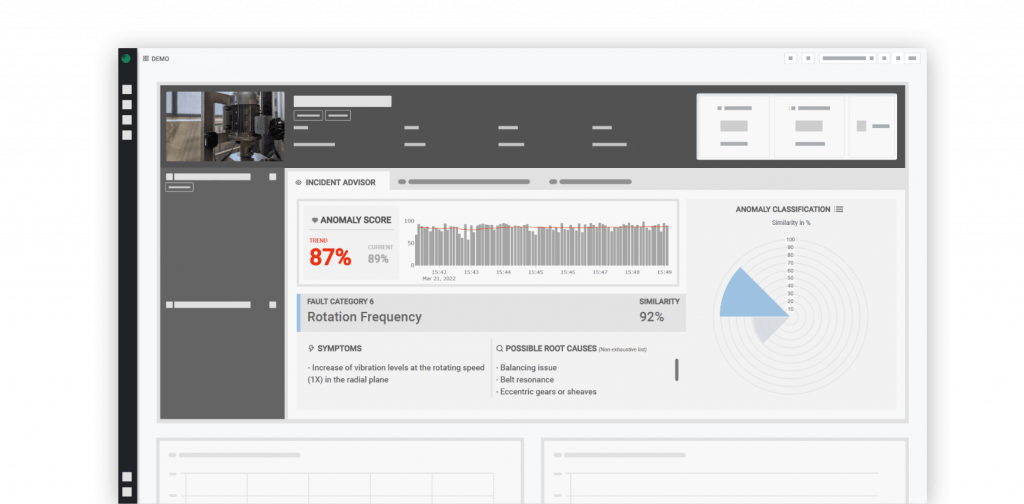

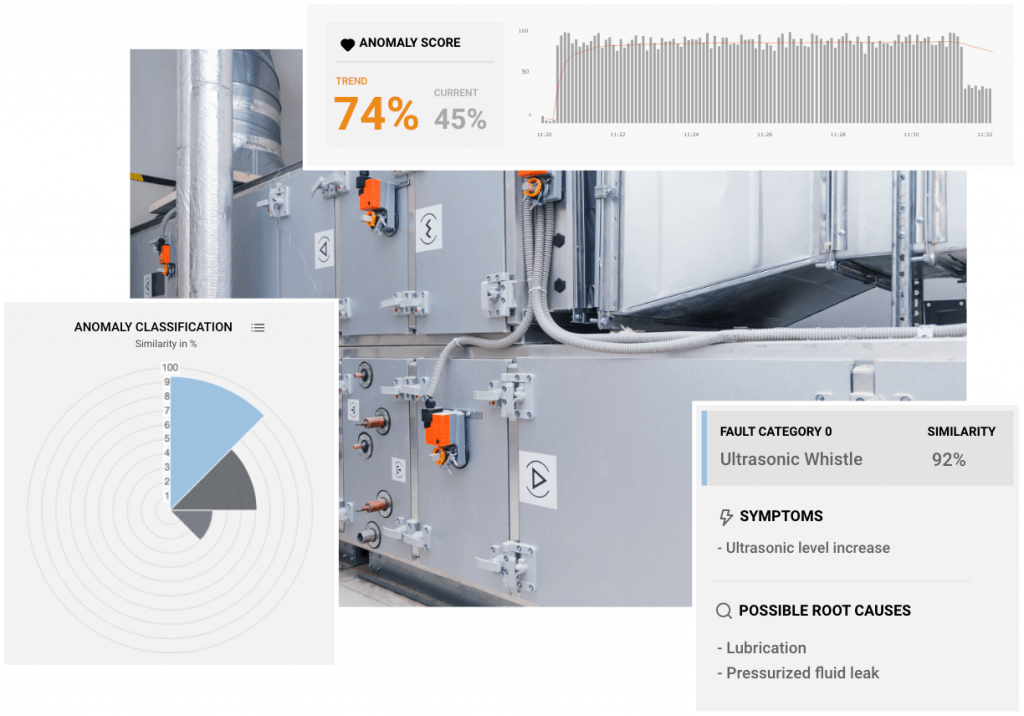

AsystomAdvisor is the combination of an anomaly detection and an advisor subsystem. The anomaly detector allows detecting unexpected changes of the machine operation when compared to a learnt vibration and ultrasonic profile representing its nominal behavior. The advisor complements this by providing recommendations about possible root causes (e.g., unbalance or bearing wear) together with a confidence level about the diagnosis. It also provides the dominating symptoms observed (e.g., increase of vibration levels in the radial plane). As we do not want our system to be a black box system, expert users can still access the raw information from the AsystomSentinel device that were fed to our AI solution to make their own opinion. That raw information is made up of roughly 50 statistical parameters representative of the vibration and sonic state (e.g., vibration RMS and peak levels or frequency band levels).

Simplified overview of AsystomAdvisor functions

Why chose AsystomAdvisor, Visualization, Diagnostics and Alert Platform?

The system has been developed with customer needs in mind. One of the challenges we faced was that our system should be usable by people with no pre-existing machine condition monitoring knowledge as well as vibration specialists. The AsystomAdvisor does not require specific expertise to be used and can be thought of as a common denominator for both novices and experts, raw information from the beacon still being accessible by the latter. Also, while our solution can easily export data to third party software tools or databases through HTTP secured APIs, it can also be used standalone, independently of any Computer Maintenance Management System as we provide both the sensors and the server-side application platform which natively includes dashboard managements, data visualization and alerting features.

What are the top key features of the solution?

As previously mentioned, ease of use and versatility are essential traits of the solution. In addition to that and from a pure technical perspective, we should add that AsystomAdvisor benefits from analyzing both vibration and ultrasonic information. This allows getting a better coverage for a wider range of anomaly causes ranging from low frequency faults for which vibration analysis is typically used to identify balancing, alignment, or looseness problems; to very high frequency faults only discoverable in the ultrasonic range like an under-lubrication condition of a rolling element bearing. Finally, the solution is suitable for a wide range of rotating machinery use cases including but not limited to pumps, compressors, or crushers to name a few.

AsystomAdvisor: anomaly detection, possible root causes advisor.

What are its top benefits?

Having a periodic stream of condition data about a machine is essential to finely follow any degradation before they lead to catastrophic failure and production stop. Being a non-intrusive and very low power radio device, our sensor can run on battery for years and does not require costly wiring setup. The bottom line is a cost effective and smart solution that can be deployed at scale in various industrial environments including outdoor or even explosive atmosphere, the device being ATEX/IECEx certified.

How does it work?

After having setup a beacon on the machine – an operation that generally does not require more than a few minutes – measurement data are sent on a periodic basis to the AsystomAdvisor platform where they get processed. After having checked that the machine is in a reasonably healthy state using ISO standard reference values, a learning of the nominal operation shall be achieved in order to follow any subsequent unexpected deviation or drifts. The interface allows the user to select a representative period of time to this end. For machines and processes with limited variability a typical two-week measurement history is required to properly define the learning phase before starting to track anomalies and their related causes.

Let AsystomAdvisor take you beyond predictive maintenance

For more details contact us: